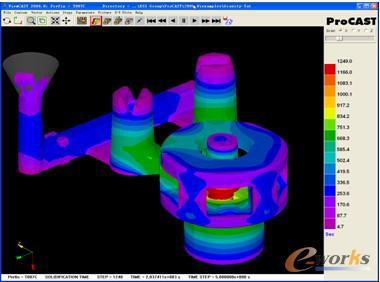

The design process of casting process involves designing the part itself, gating system, feeding system design, vent design, design chilling systems, special casting process design and so on.

|

|

Part allowance related to the process design itself, pouring position, select parting, select casting process parameters, dimensional tolerances, shrinkage of parts, draft angle, the correction amount, type a negative such as the design.

Pouring molten metal into the system is to guide the mold cavity of the channel, gating system design was reasonable or not, it affects the quality of the casting is very large, easy to cause various types of casting defects, such as: water shortage, cold traps, red sand, slag inclusions, sand, etc. casting defects. Casting gating system design, including the choice of the type of system, cross-sectional dimensions of each component within the gate location selection and gating system OK. Moreover, the choice of gating system is also very important, then how can we choose the right gating system?

For mechanized assembly line, mass production, in order to facilitate the production and help ensure the quality of the casting, ingate generally set in the mold parting line, according to the choice of casting blank location and parting the casting, the inner pouring Road opened in the mold parting line are "intermediate injection style" casting system. Liquid metal in the casting process will inevitably contain certain "slag", in order to improve the ability of slag gating system, suitable for the use of "closed" casting system.

In the casting process, the casting process of designing a great impact on the quality of the cast product, but the choice selection method of pouring system can not be ignored.

Feeding system design is reasonable design riser and subsidies to compensate for the casting liquid produced during solidification and solidification shrinkage state, in order to obtain a sound engineering technology casting .

Cavity vent for discharging gas, the ability to improve the liquid metal filling, filling the first cavity to exclude subcooled liquid metal and dross, but also whether the mark as observed pouring cavity .